2000HP Oilwell E2000 Drilling Rig Specification

- Oilwell E2000 single drum 2000HP draw works (s/n H-47-1600) with Elmagco 7838 electric brake (s/n TA-11138W)

- PERMA brake lubrication device, FOSTER catheads, OMRON console and powered by (2)1000 HP GE 752 electric motors (Inspected)

- Lee C. Moore 142′ x 30′ Base + 31′ High Beam Leg Raised Floor

- Cantilever Type Mast having a rated static hook load capacity of 1,300,000 lbs. per API Standard 4E with 14 lines strung to the traveling block. 800 ton skewed Type Crown Block having one 60″ diameter fabricated steel working sheaves mounted on tapered roller bearings.

- Deadline on off-drillers side. Sheaves grooved for 1 1/2 diameter wireline (s/n T 3844)

- Lee C. Moore swing-up substructure, 30′ floor height, 26′ clear height, 1,300,000 lb casing capacity simultaneous with 800,000 lb. setback capacity at 31′ elevation (s/n 73844)

- (2) A1700-PT triplex mud pumps rigged out with pulsation dampners, pressure relief valves, electric oilers and powered by (2) GE 752 each(Inspected)

- (3) Caterpillar 399 Diesel Engines with 1050 KW Kato Generators (ran out) mounted on covered generator oilfield skids.

- Ross Hill 4 x 4 SCR house with 2000 Amp breakers, Modern feed from bus bar for top drive 600 V feed to VFD House (Rebuilt)

- Oilwell 500 Ton Block (s/n 020-026) with BJ 5500 Dynaplex hook(s/n 931)

- National P-650 Swivel (s/n 651-10)

- CanRig 500 Ton Model 1050E-500 with Drive House

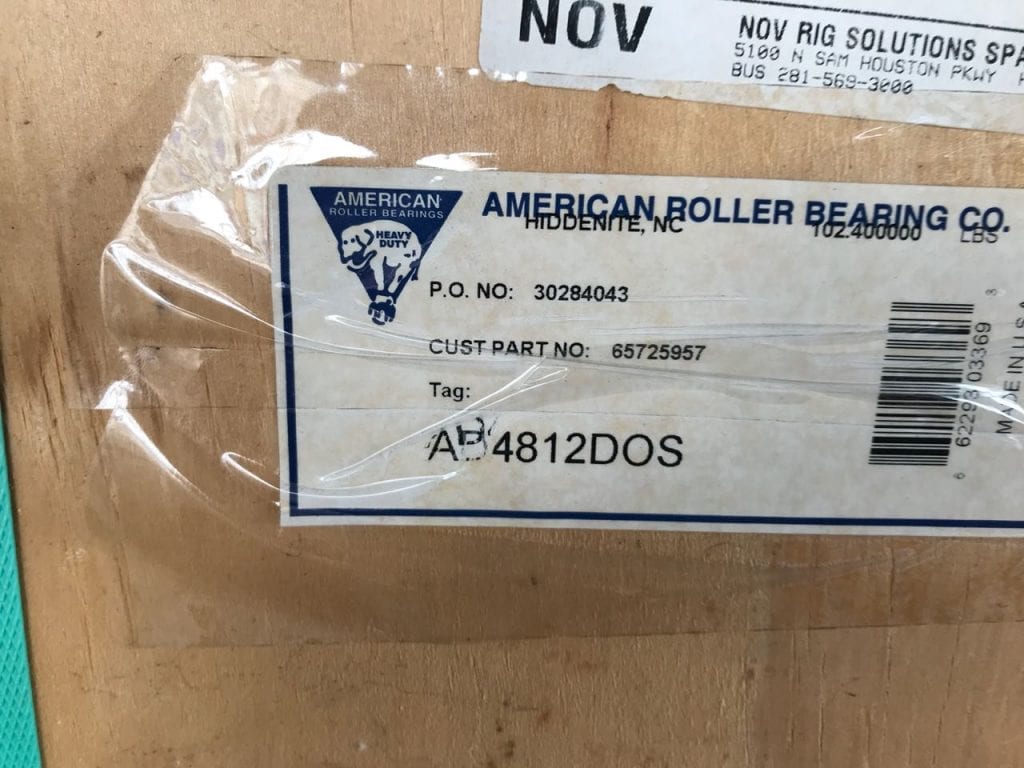

- NOV 3080 Iron roughneck (s/n 1044)

- Oilwell 27 1/2 ” Rotary Table (s/n 688)

- Koomey 180 gal 7 station air and electric accumulator with remote (s/n 2503)

- (3) Mud Tanks with stirrers, shakers, electric centrifugal pumps, de-sander, de -ilter, cyclone, Swaco mud degasser.

10 x 45 Pusher House (s/n 125-113) - Junk Box with misc, 25 lift subs, 15 cross over-bit subs, mud bucket, Kelly drive bushing, elevator bails, solid master bushing,13 5/8 ” 5000 drilling spool, vibrator hose, Kelly valve, dart valves.

- Trip Tank, oil bin, catwalk, V-Door, Driller Dog House, ODS Dog House mud mixing house, fuel tank, derrick stand, water tanks, suitcases, survey unit, combination storage house, pump parts house, (linears, rods, etc) hand rails, shaker screen box.

- Air compressors.

The Oilfield Equipment related post 2000HP Oilwell E2000 Drilling Rig Used with CAT Certification is from Flowtech Energy. Looking for Oilfield Equipment including New, Used, Remanufactured and Surplus Oilfield Supply, check out our inventory or call our toll free number at 877-645-6693 for more information.